Manufacturing Process Flowchart Complete Guide

Ready to Create Your Manufacturing Process Flowchart?

EdrawMax specializes in professional diagramming and visualization. Discover everything you need to know about manufacturing process flowcharts in this comprehensive guide. Start creating your own today with a free trial!

Given the inherent complexity of manufacturing processes, managers consistently seek effective methods to clearly explain each component to involved personnel and prevent production errors. However, verbal communication often proves insufficient for comprehensive explanation. Flowcharts serve as powerful tools for creating intuitive visual aids that simplify complex processes.

Manufacturing process flowcharts represent essential instruments for process analysis. Manufacturing personnel, particularly supervisors and managers, utilize these visual tools to emphasize operational sequences and priorities on the production floor. This article explores the significant benefits of manufacturing process flowcharts and provides practical tips for efficient creation.

1. What is a Manufacturing Process Flowchart?

As the name implies, a manufacturing process flowchart represents a specialized diagram that visually illustrates the sequential steps within a manufacturing operation. Historically, these flowcharts were manually drawn, but modern technology enables software solutions like Excel to produce standardized flowcharts. Advanced tools even allow customization to clearly present process activities alongside their inputs and expected outputs.

Within manufacturing process flowchart templates, specific shapes and symbols represent each step. These visual elements connect through lines and arrows to indicate operational flow. This design methodology provides quick reference for users, reducing misinterpretation risks and enhancing production floor time management.

2. When to Use Manufacturing Process Flowcharts?

Manufacturing process flowcharts serve as essential tools for managers simplifying production employee training and orientation. These diagrams prove particularly valuable in these scenarios:

- Demonstrating process execution procedures

- Identifying operational improvement opportunities

- Facilitating communication and collaboration among process stakeholders

- Documenting standardized processes

- Introducing new manufacturing processes

- Project planning and implementation

3. Flowchart Symbols and Their Meanings

Flowcharts utilize symbols as primary communication elements regardless of type. Standard manufacturing process flowchart templates employ a fixed set of primary symbols to represent fundamental elements. Lines and arrows depict activity flow or decision consequences. The table below outlines primary symbols denoting standard flowchart elements.

Various flowchart shapes accommodate different diagram types. Each symbol carries specific meaning and contextual appropriateness. Whether reading or creating flowcharts, understanding common symbols facilitates comprehension. Below are five fundamental flowchart symbols universally employed:

- The Oval or Pill Shape indicates process start/end points

- The Rectangle Shape represents an execution process

- The Parallelogram Shape denotes information input/output

- The Diamond Shape signifies decision points

- The Arrow Shape illustrates sequence flow direction

Source: EdrawMax

Manufacturing setups vary significantly across industries. Lean manufacturing implementations often feature straightforward setups minimizing waste and delays, while mass production facilities handling diverse products require more elaborate configurations. For instance, hair product manufacturers may create multiple flowcharts incorporating machinery symbols for different product formulations. Consequently, many manufacturing process flowchart templates include specialized symbols representing equipment or unique processes. For comprehensive information about additional manufacturing flowchart shapes and symbols, explore Manufacturing Flowchart Symbols.

4. Free Manufacturing Process Flowchart Examples

Maximizing flowchart effectiveness begins with selecting the appropriate diagram type for your specific process. These examples illustrate various flowchart applications for typical manufacturing scenarios:

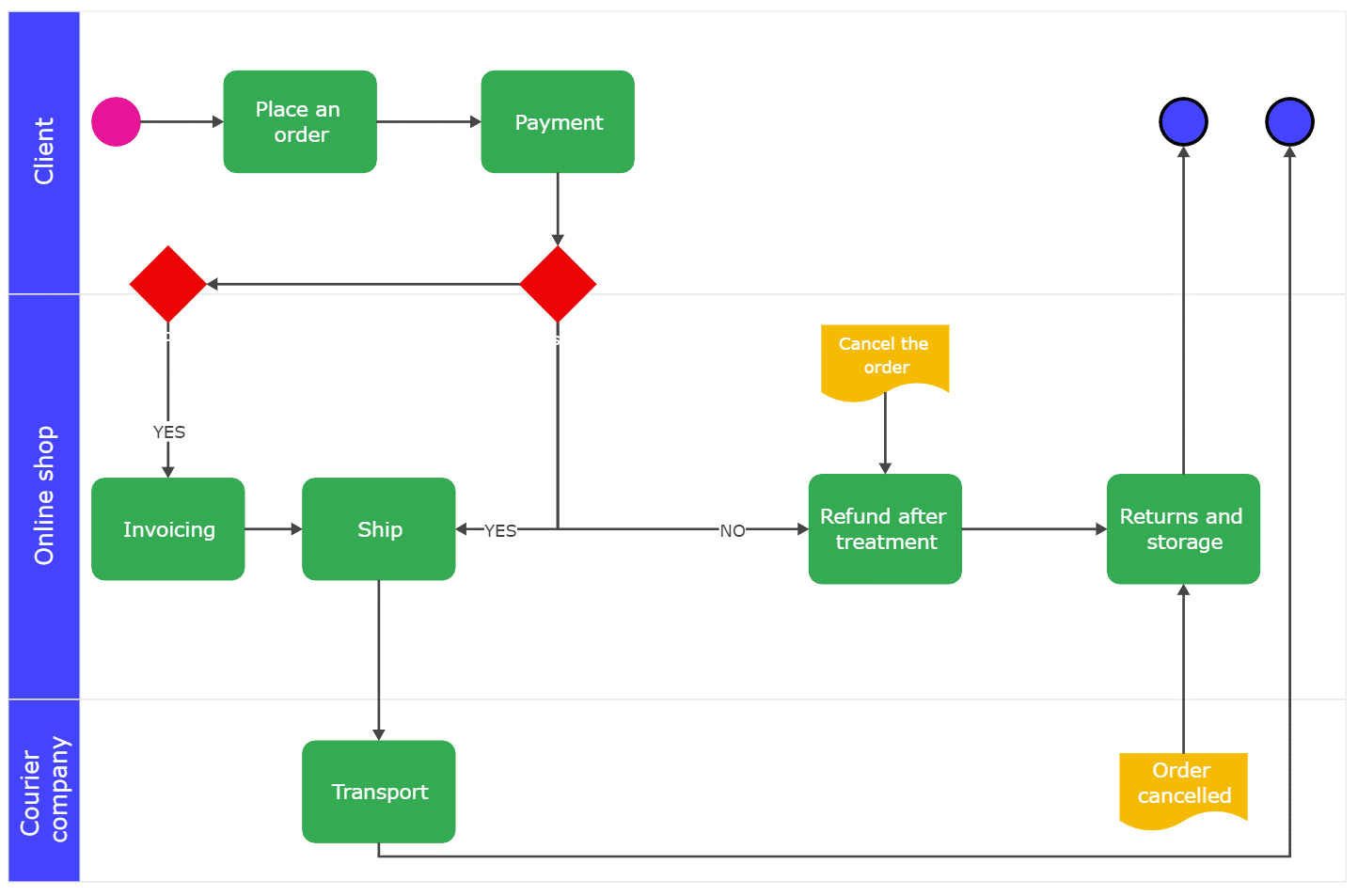

- Swimlane Diagram

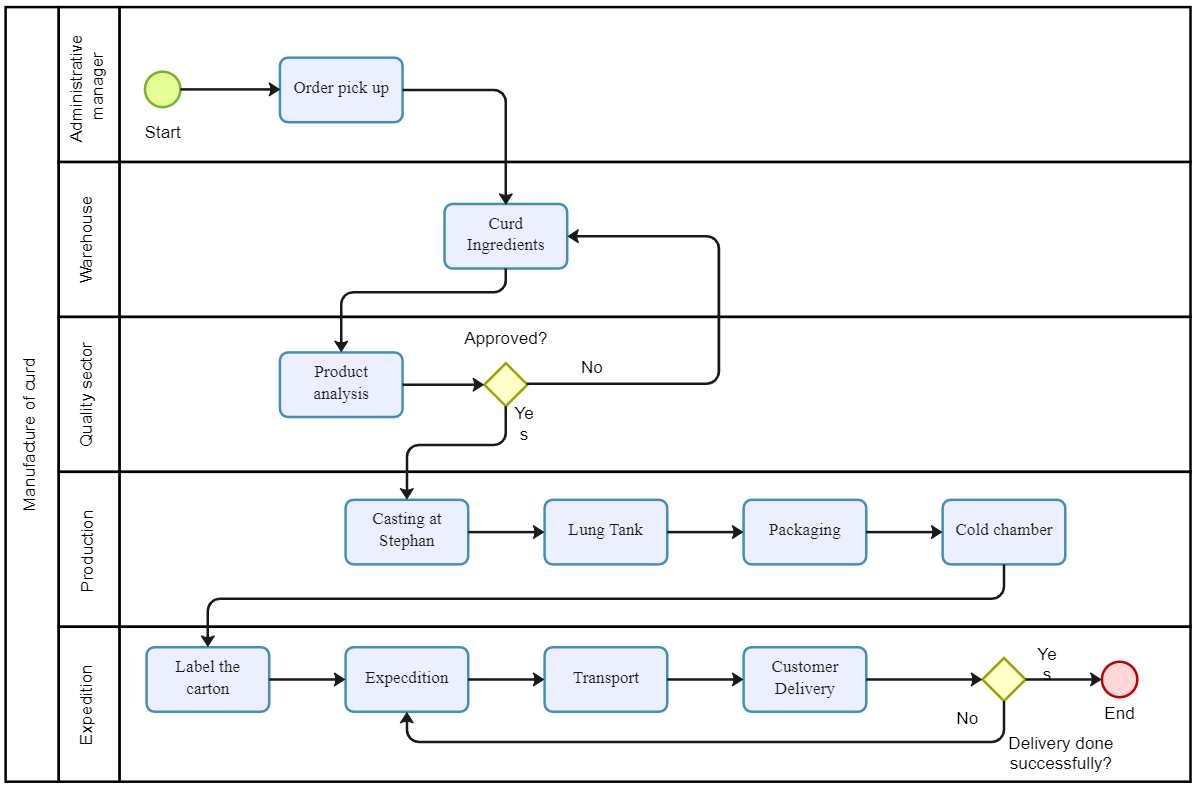

- Manufacturing Process Flow Diagram

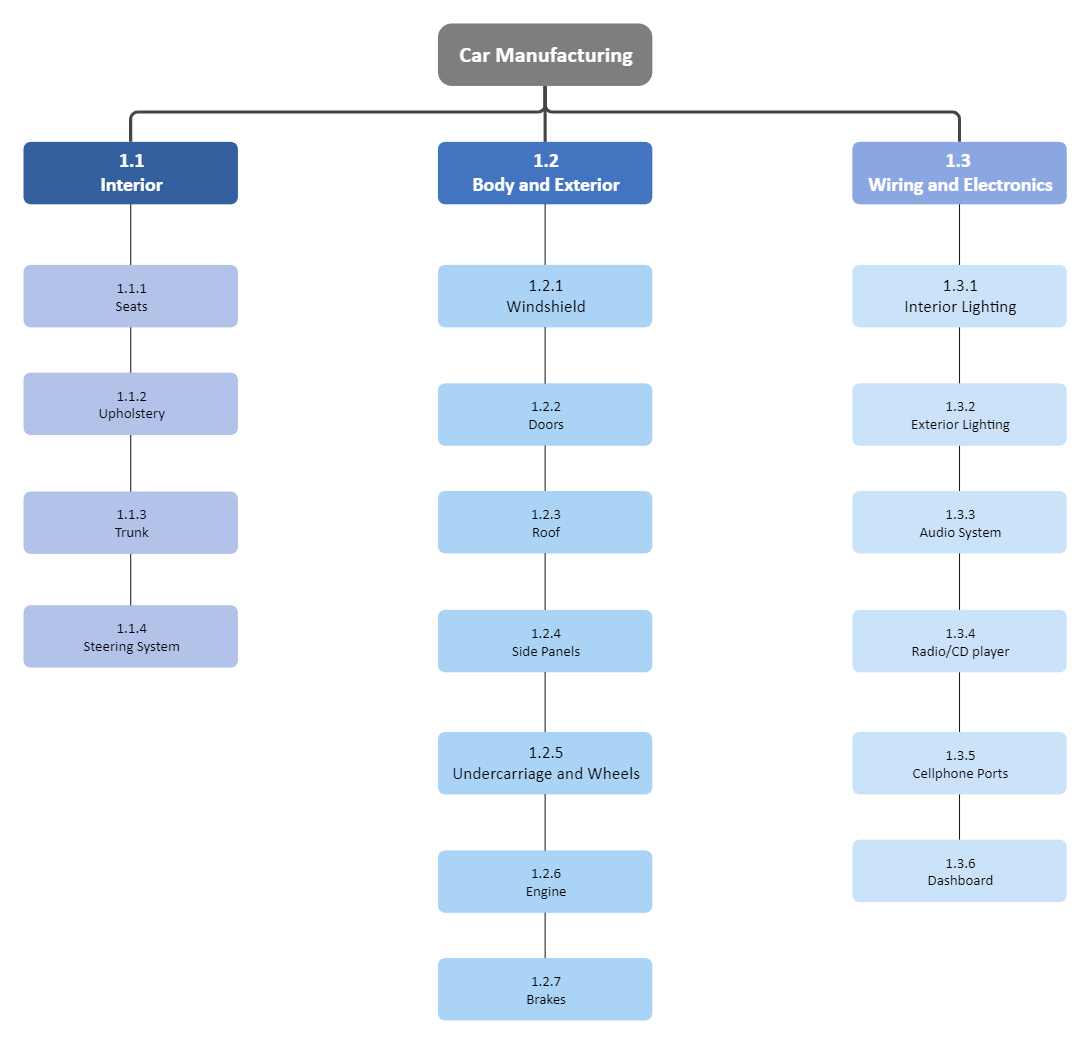

- Car Manufacturing WBS Template

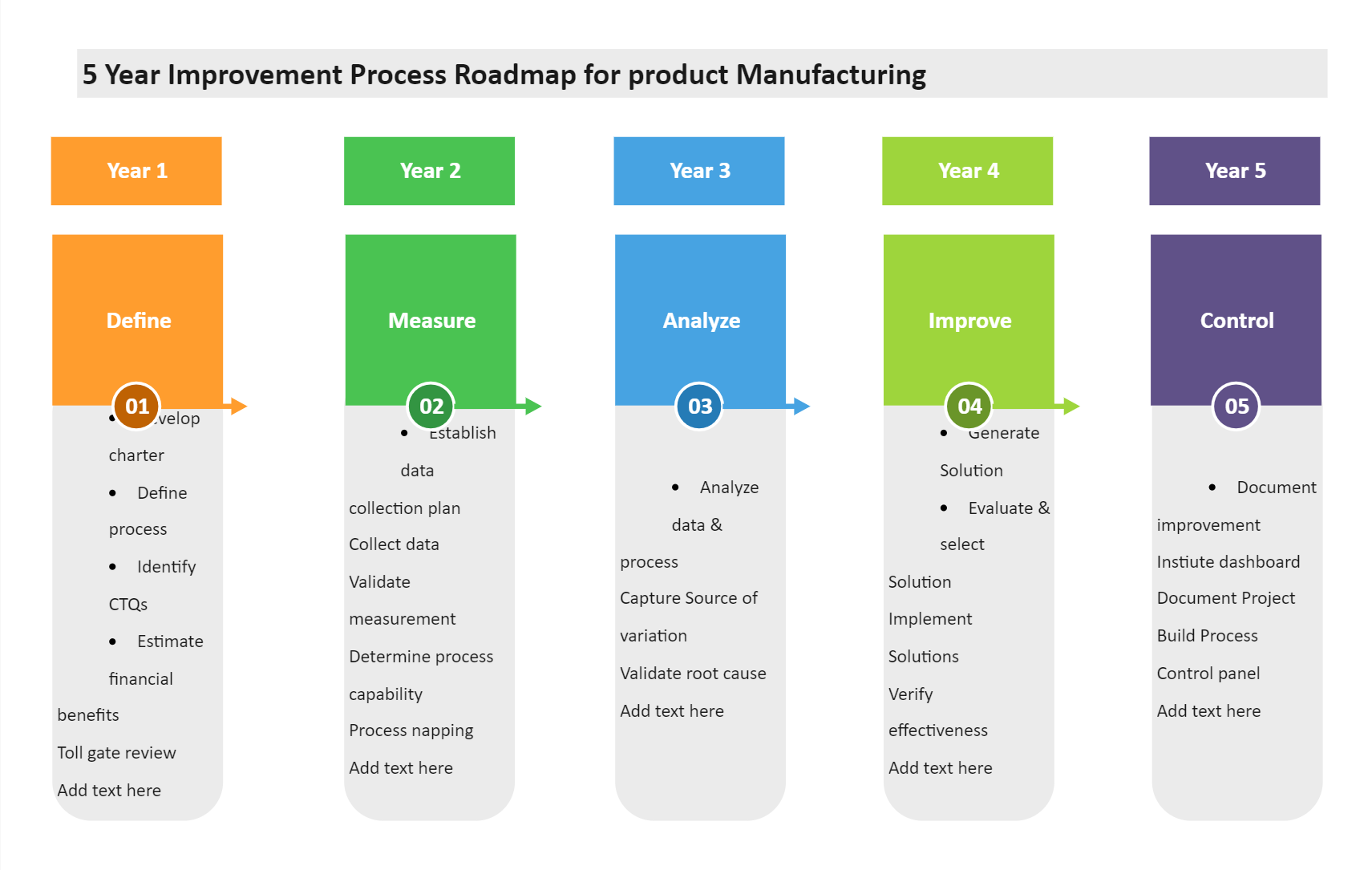

- Product Manufacturing Process Roadmap

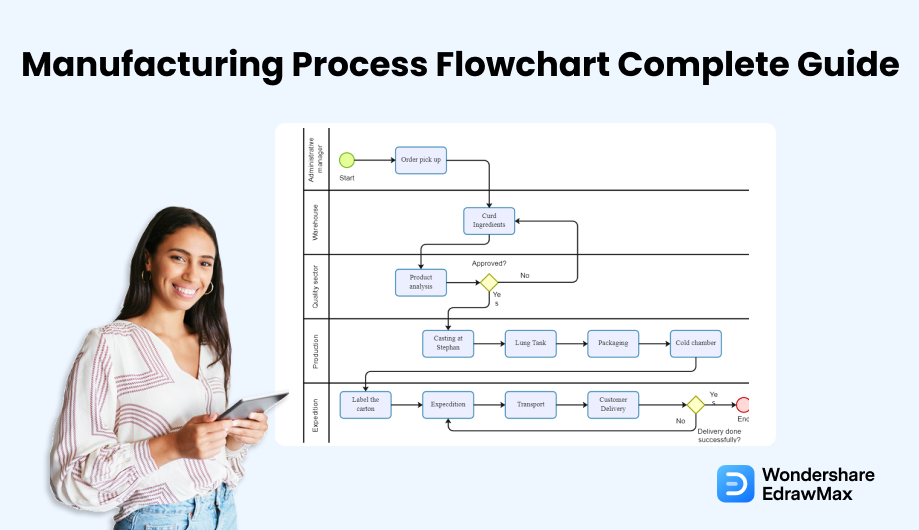

Example 1. Swimlane Diagram

Modeled after swimming pool lanes, swimlane diagrams organize process frameworks from start to finish based on categorical divisions that visually separate responsibilities among process participants. Lanes may represent specific departments or employees responsible for completing all subprocesses within their designated area.

Example 2. Manufacturing Process Flow Diagram

Manufacturing process flow diagrams serve as extensively utilized optimization tools for process improvement and delay elimination. These diagrams illustrate material movement from raw material arrival through final product delivery to end users.

Example 3. Car Manufacturing WBS Template

Specifically designed for automobile production, this flowchart template details the complete activity breakdown required for vehicle assembly. Numerous automotive manufacturers utilize this diagram type to create lean manufacturing process flowcharts that rapidly identify improvement opportunities and eliminate production bottlenecks.

Example 4. Product Manufacturing Process Roadmap

This flowchart type encompasses the strategic direction and progress vision established by companies for specific products or product lines. Unlike previous examples, process roadmaps outline management initiatives designed to sustain and enhance product manufacturing processes.

EdrawMax

All-in-One Diagram Software

- Superior file compatibility: Import and export drawings to various file formats, such as Visio

- Cross-platform supported (Windows, Mac, Linux, Web)

5. How to Improve Your Flowchart-making Skills

Creating effective manufacturing flowcharts doesn't require advanced technical expertise. Implement these practical tips to develop functional manufacturing process flowcharts for your organization:

- Establish Clear Objectives: Define specific goals before creating your flowchart. This strategic approach enables optimal flowchart type selection and effective presentation for target audiences.

- Maintain Visual Consistency: Consistent formatting remains essential for professional flowcharting. Standard manufacturing process flowchart templates facilitate this consistency.

Ensure coherent symbol usage and proper component alignment for effective flowcharts. Consider incorporating aesthetic elements like color coding to enhance visual appeal and comprehension. - Utilize Single-Page Design: Contain all flowchart elements on one page to facilitate easy step tracing and sequence understanding. For complex processes, consider partitioning into separate logical flowcharts.

- Customize for Your Audience: Tailor flowchart attributes according to your target users. Employ simplified shapes and symbols for non-technical audiences, while incorporating technical details for specialized viewers.

6. Conclusion

Modern technology provides diverse flowcharting software options for creating manufacturing process flowcharts. Success requires firsthand process knowledge and effective communication skills to ensure relevant information reaches all involved personnel clearly.

As a versatile diagramming solution, EdrawMax offers comprehensive manufacturing process flowchart templates. Users can employ these templates for standard flowcharts or create custom diagrams meeting specific requirements. Explore EdrawMax's capabilities to begin your flowcharting journey with convenience and professional results.

Flowchart Complete Guide

Explore our comprehensive guide covering all flowchart aspects, including types, symbols, and creation techniques.