Quality Control Flowchart

Ready to Create Professional Quality Control Flowcharts?

EdrawMax specializes in professional diagramming and visualization. This comprehensive Quality Control Flowchart guide covers everything you need to know. Download now and start creating with our free trial!

Quality control extends far beyond simply monitoring product composition. It represents a systematic approach to ensuring manufacturing processes adhere to planned specifications, delivering consistent product quality and service excellence. This department has become essential for leading companies, implementing processes that not only maintain but continuously improve product and service quality through proper maintenance protocols.

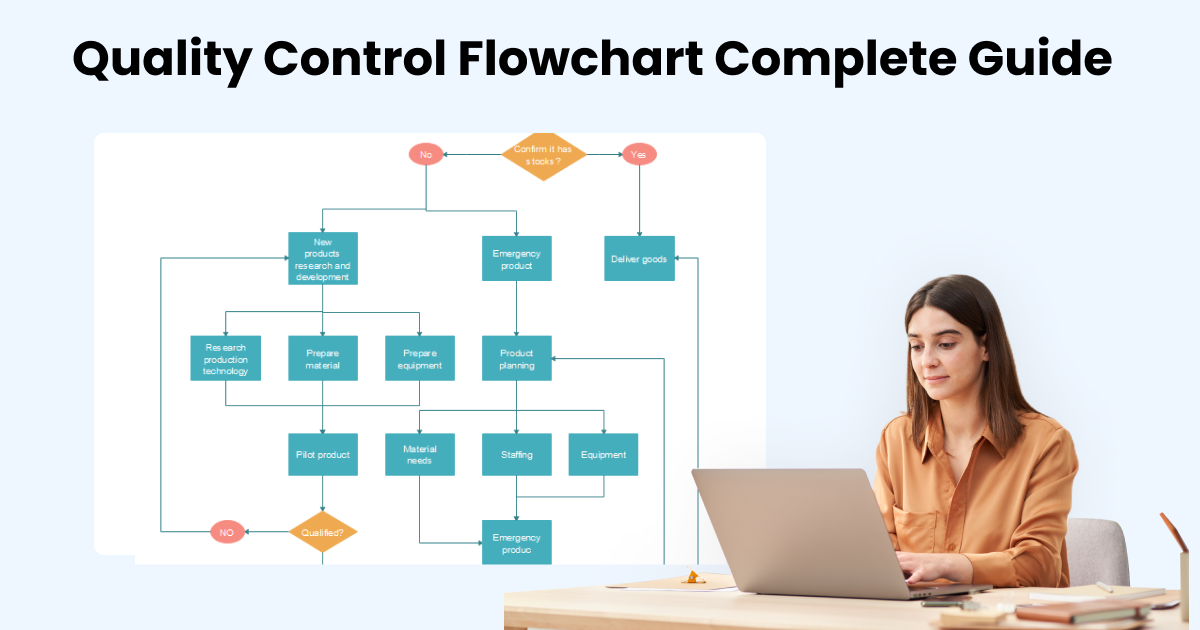

A flowchart provides visual representation of organized steps to follow specific processes. The quality control flowchart systematically arranges various components to manage product or service quality throughout manufacturing. Businesses can select from different templates and styles that align with their specific operational plans.

Various software solutions exist for creating professional diagrams. EdrawMax offers built-in editable templates and comprehensive symbol libraries to help you create customized quality control flowcharts efficiently.

1. What is Quality Control?

Quality Control (QC) extends beyond manufacturing businesses monitoring product flaws and implementing corrective actions. It represents a comprehensive process that drives business perfection through well-defined controls and standards. A quality control process ensures your organization delivers consistent products, services, and customer experiences. This systematic approach makes it easier to monitor operations, delegate responsibilities, and even expand to new locations while maintaining quality standards. The process forms a critical component of any well-run business operation.

Quality control processes apply to all business types, whether product-based or service-oriented. Sustainable business growth demands quality products, exceptional services, and careful attention to customer satisfaction. Substandard products or services ultimately reduce profit margins and make it increasingly difficult to attract and retain both customers and employees.

Well-defined quality control processes help standardize your products and services while establishing appropriate response protocols for quality issues. These systems make it easy to specify which production activities different personnel must complete, thereby minimizing errors and ensuring consistency.

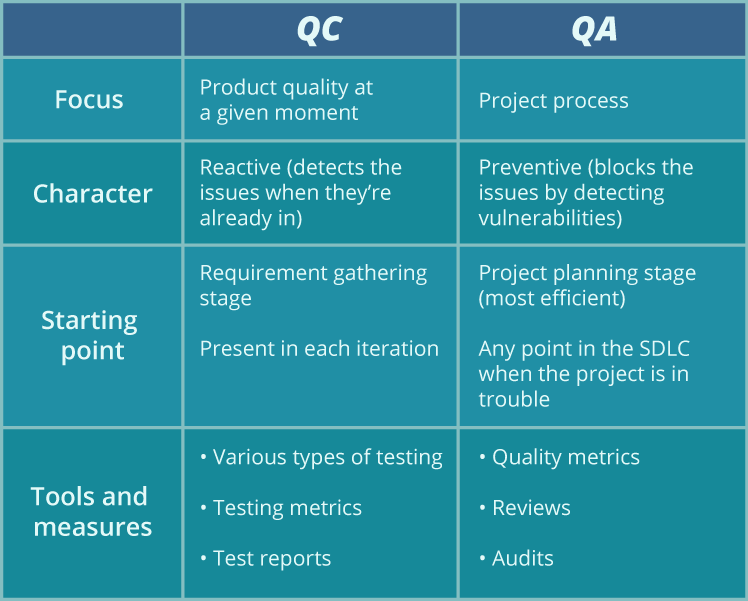

2. Differences Between Quality Assurance (QA) and Quality Control (QC)

QA and QC both form essential components of comprehensive quality management systems. QA focuses primarily on how products are manufactured or how processes are performed, while quality control emphasizes the inspection aspects of quality management. Quality assurance provides confidence—both internally to management and externally to customers and regulators—that quality requirements will be consistently fulfilled.

Fundamentally, QC encompasses the operational activities and techniques used to fulfill quality requirements, while quality assurance represents all planned and systematic activities implemented within the quality system that demonstrate products or services meet established quality standards.

Quality Control (QC):

-

Quality control evaluates products after manufacturing to identify and resolve problems

-

It represents a reactive measure that occurs after product completion and demonstrates effects

-

Applicable only after product completion for quality verification purposes

-

Utilizes various tools and tests to detect product defects, such as Canary testing methodologies

-

Incorporates software testing metrics that help determine testing reliability and effectiveness

-

Generates comprehensive test reports based on software testing to analyze data quality

Quality Assurance (QA):

-

Quality assurance represents management's role in ensuring smooth manufacturing processes

-

It functions as a preventive measure to detect and resolve issues during manufacturing

-

Integrates consistently throughout the software development life cycle (SDLC) to ensure quality

-

Utilizes quality metrics to analyze QA process effectiveness and ensure step accuracy

-

Quality reviews help determine customer satisfaction and maintain product quality standards

-

Quality auditing ensures compliance with government standards during product production

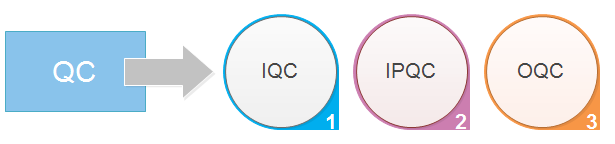

3. Types of Quality Control

Understanding how quality control operates requires examining its various methodologies. QC implementation demands strategic planning, time investment, financial resources, and unwavering commitment to quality standards.

Different quality control approaches exist, with your specific product or service determining the most appropriate methodology. Management can choose between internal or external quality control inspections based on organizational systems and requirements.

Internal Vs. External Quality Control

The internal quality control process relies on established in-house protocols to monitor systems. These protocols may include running standards and controls, routine equipment verification, and comprehensive employee data analysis.

External quality control becomes relevant when products or data are sent to affiliated external businesses. For example, a food production company might verify nutritional value analysis by sending products to external laboratories. Third-party verification plays a crucial role in validating production methods and ensuring compliance with standards.

Statistical Quality Control

This QC type requires extensive statistical methodology application. Statistical tools are automated to operate within models requiring minimal manual intervention. Acceptance sampling forms a critical component of statistical quality control, conducted post-production to assess quality parameters defined by organizational standards for attributes and variables.

Process Control

Similar to how all products begin with components, this quality control type ensures company processes function correctly to produce well-finished goods. It verifies whether activities at each process stage operate within acceptable variation ranges, representing a vital quality management component that ensures proper machine operation and flaw-free products.

Types of Quality Control Process (With Examples)

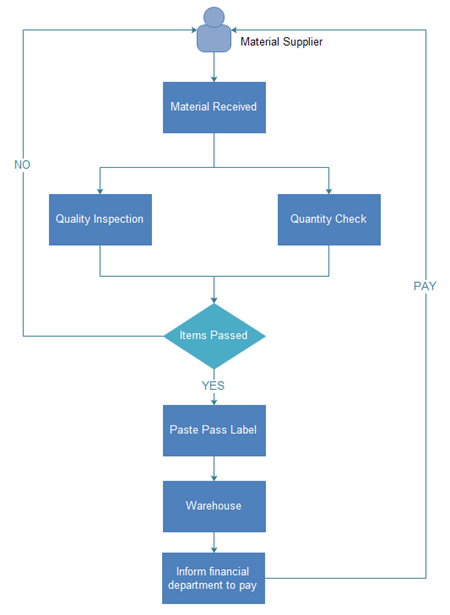

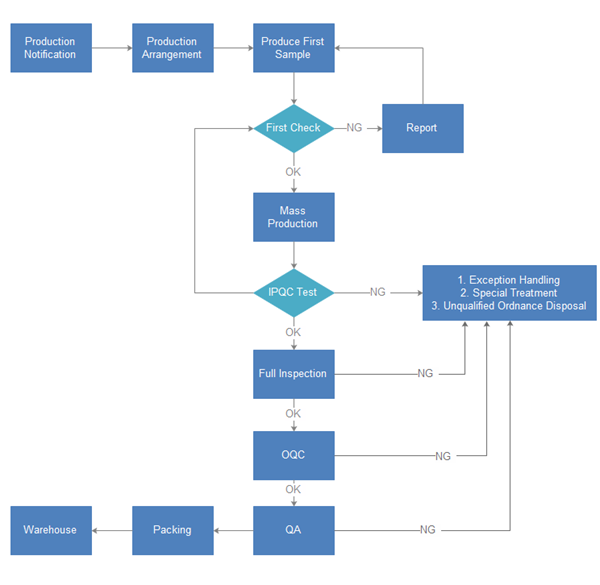

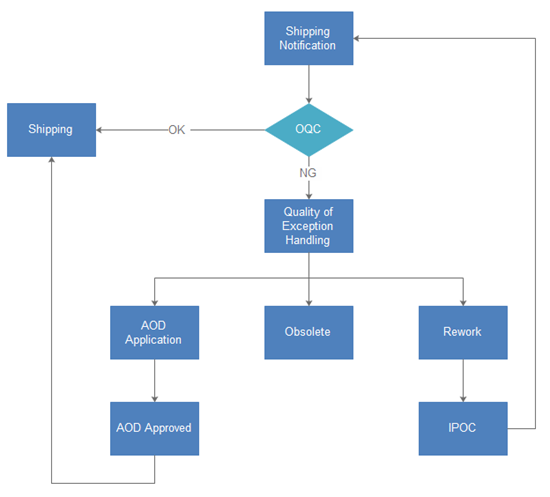

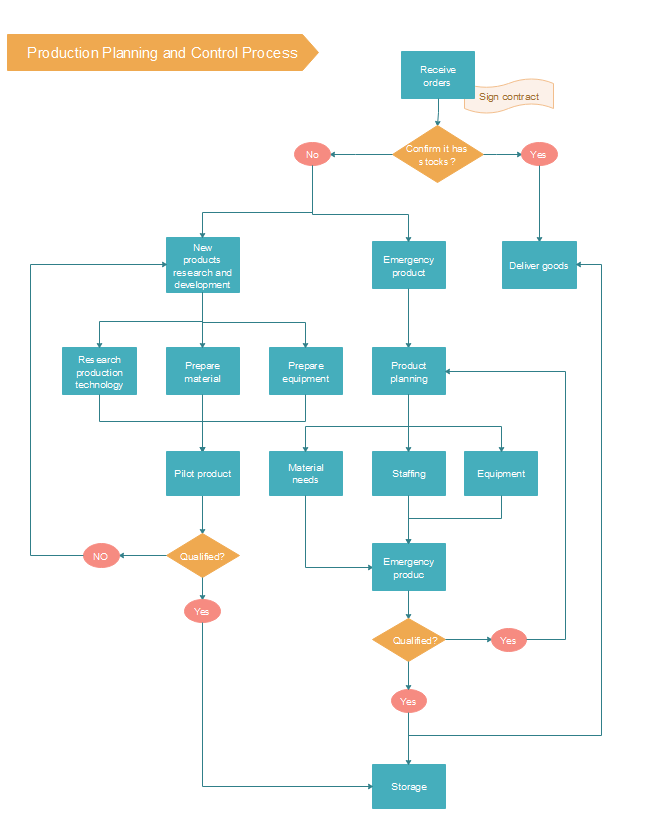

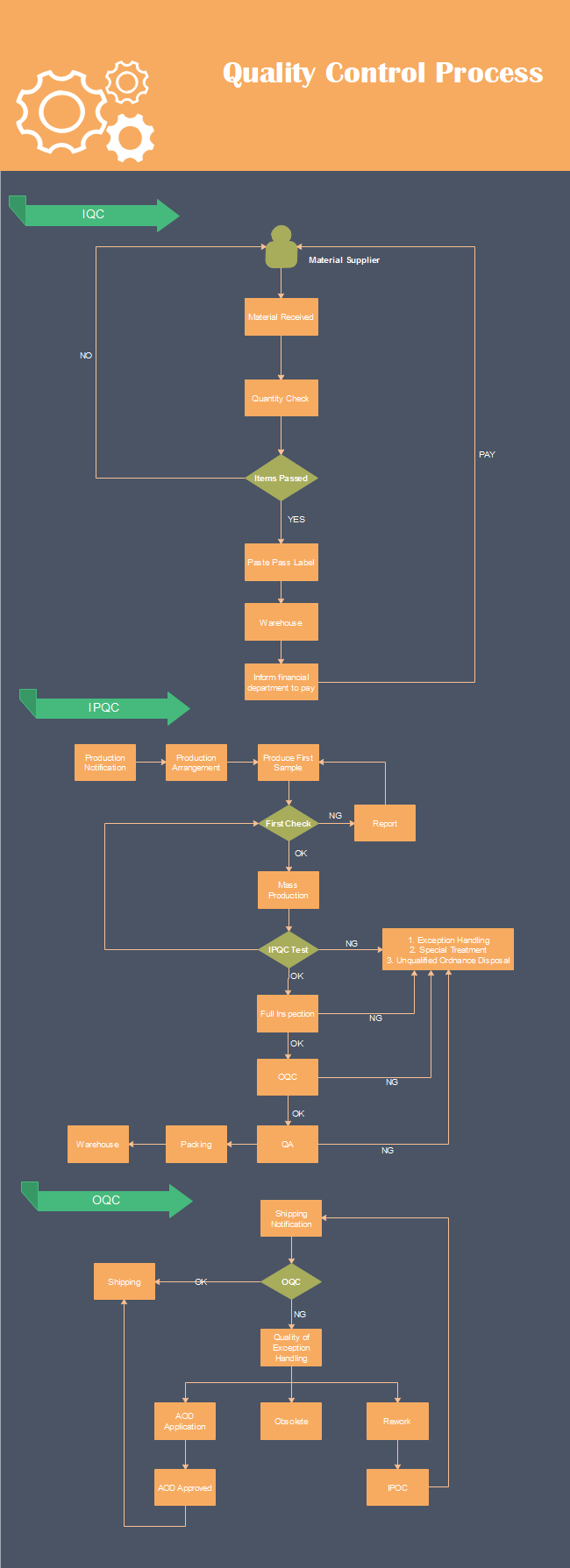

The quality control process divides into three distinct components: IQC (incoming quality control), IPQC (in-process quality control), and OQC (outgoing quality control).

- IQC - Incoming Quality Control

Incoming quality control involves inspecting raw materials and components from suppliers upon arrival. When defective parts are identified, negotiations with suppliers for returns or exchanges ensure product quality remains unaffected. Below demonstrates a sample IQC process flowchart.

- IPQC - In-process Quality Control

IPQC refers to quality control during assembly processes. Its crucial nature enables early detection and resolution of problems before they escalate.

- OQC - Outgoing Quality Control

OQA represents final product inspection before shipping, serving as a crucial step in ensuring defect-free shipments.

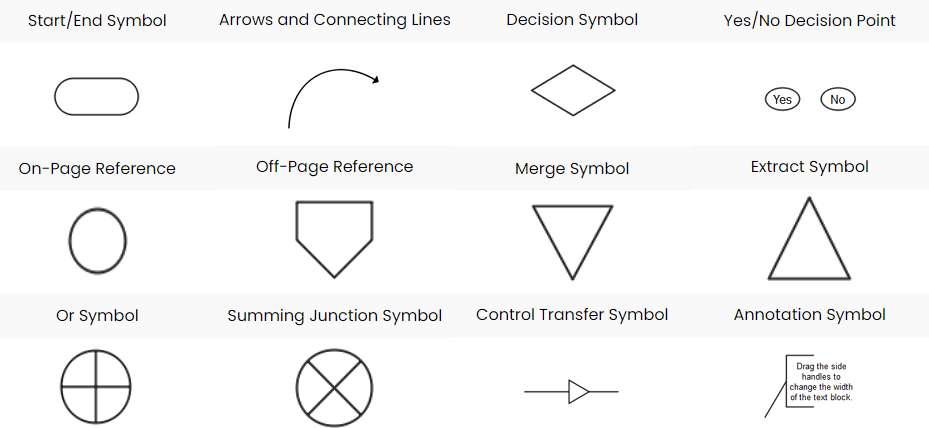

4. Quality Control Flowchart Symbols

Quality control flowcharts utilize various standardized symbols. Understanding these symbols' meanings and applications enables rapid and accurate flowchart creation. Explore Flowchart Symbols to discover additional symbols and types.

Source: EdrawMax.com

5. How to Make a Quality Control Flowchart?

While creating quality control flowcharts may appear complex, online flowchart tools simplify the design process significantly. Follow these straightforward steps that designers and engineers can use to create professional flowcharts.

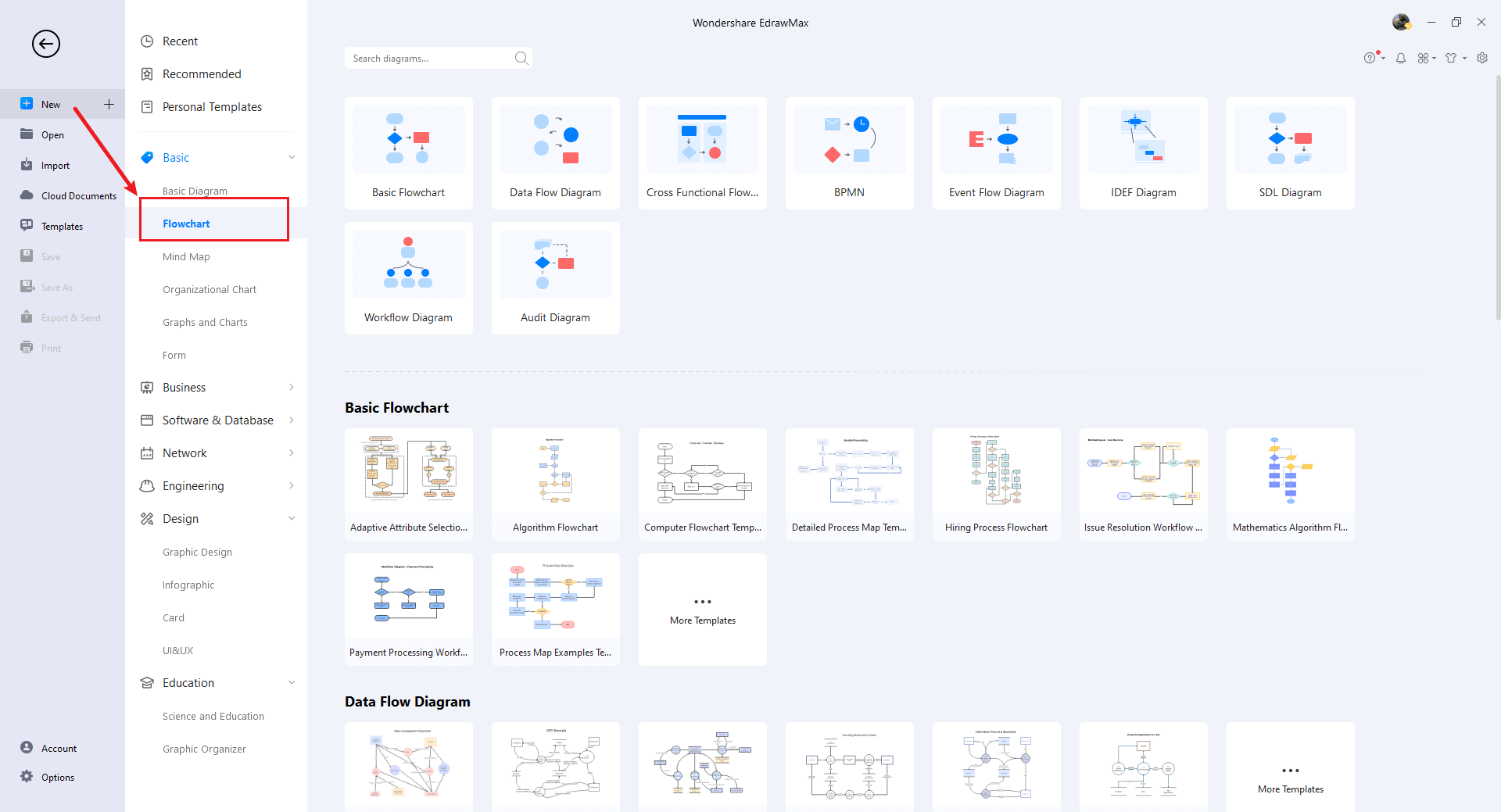

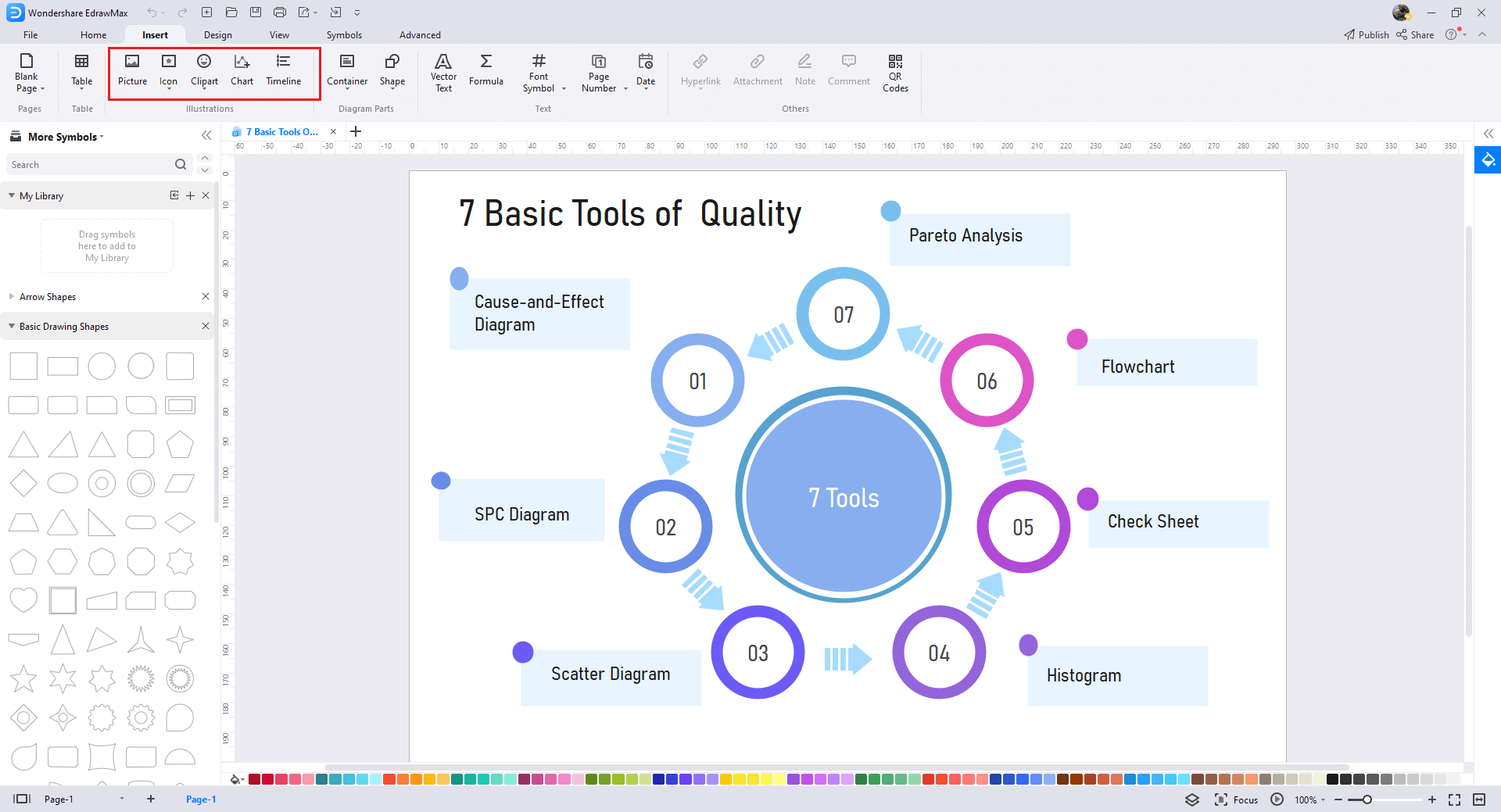

Step1 Open EdrawMax and Login

Begin by installing EdrawMax on your system. Visit EdrawMax Download and select the appropriate Quality Control Flowchart software for your operating system. For remote team collaboration, access EdrawMax Online and login using your registered email credentials.

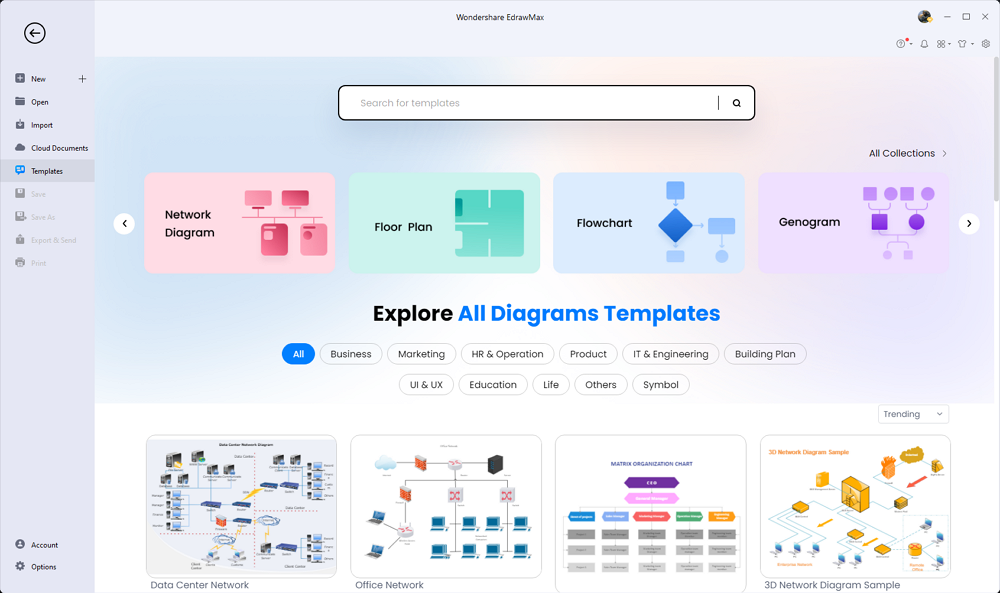

Step2 Select a Template

After launching, the Home screen displays by default. Navigate to the Template bar and search for Biology Diagrams. Built-in templates matching your search will appear. EdrawMax features an extensive template library with over 25 million registered users who have created comprehensive Templates Community resources. Select your preferred template and click Use Immediately to open it in a new customization window.

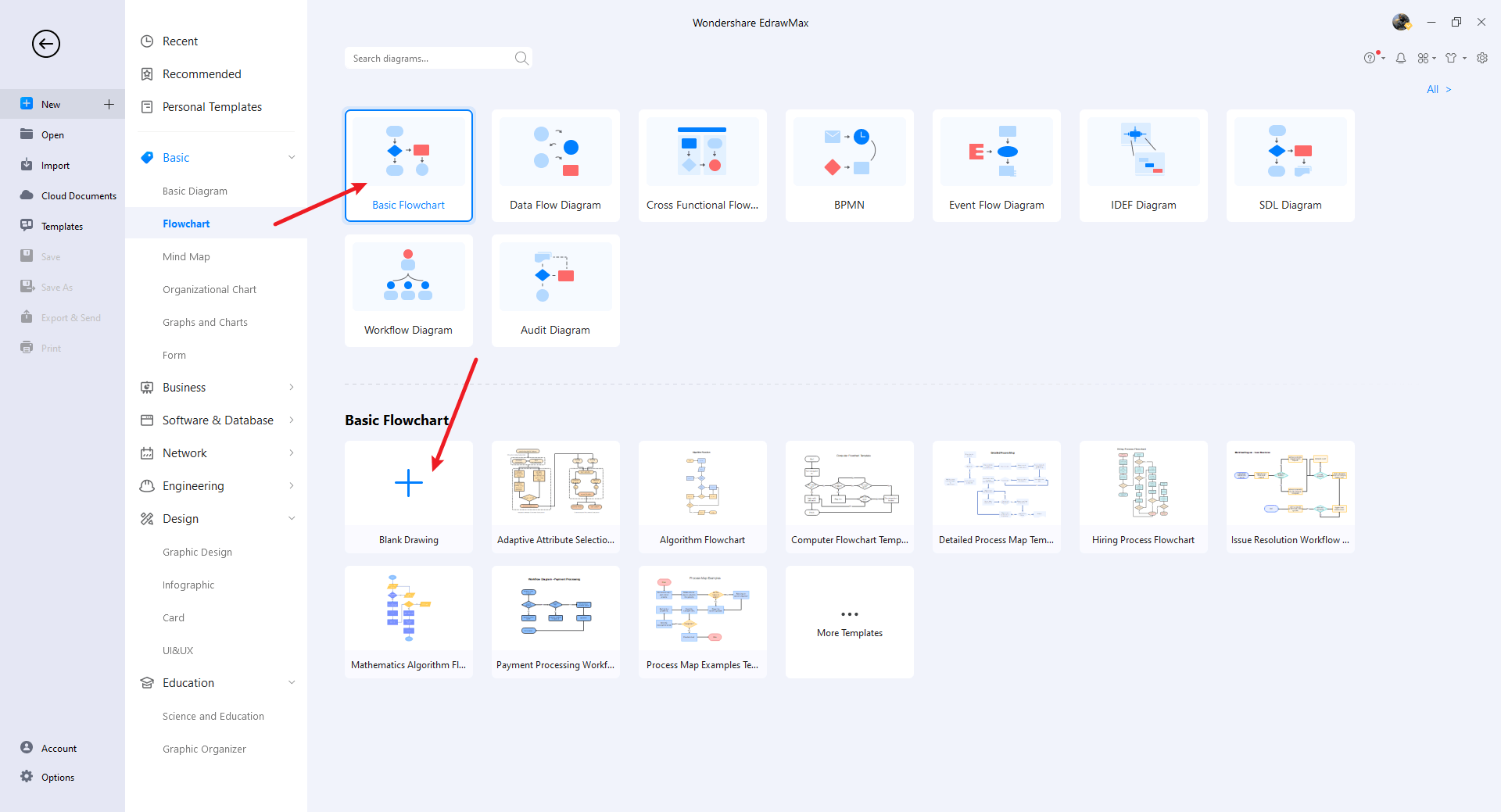

Step3 Create From Scratch

From the EdrawMax homepage, locate the '+' sign that directs you to the canvas board, where you can initiate Quality Control Flowchart design from scratch. Combined with your technical expertise, utilize the extensive symbol library to create detailed Quality Control Flowcharts.

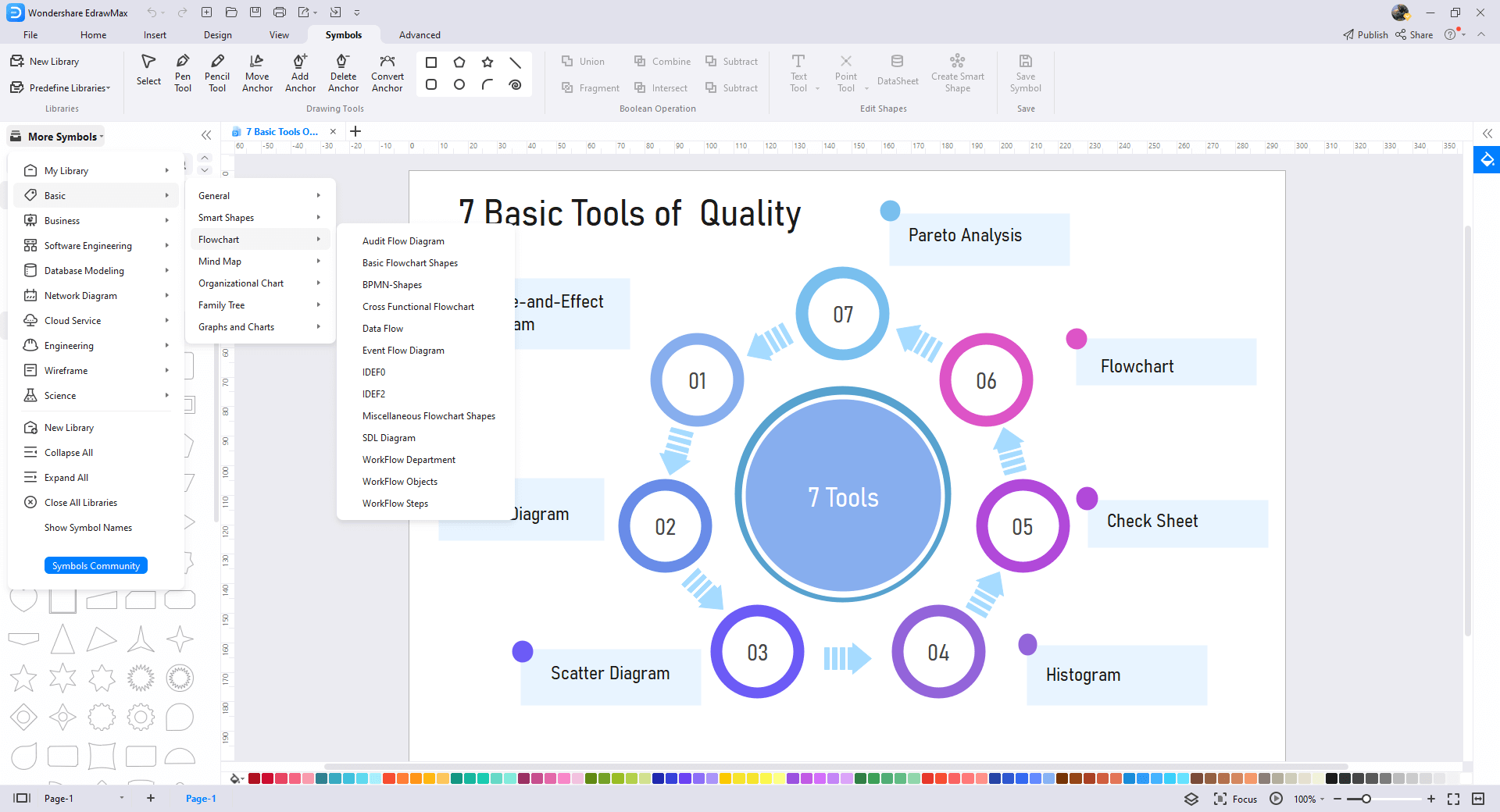

Step4 Select Symbols

EdrawMax includes extensive symbol libraries containing over 26,000 vector-enabled symbols for rapid diagram creation. If required symbols are unavailable, easily import images/icons or create custom shapes saved as symbols for future use. Navigate to the 'Symbols' section and select 'Predefined Symbol' from the top toolbar to access hundreds of symbol categories for your Quality Control Flowchart.

Step5 Add Components

After sketching basic components, customize fonts, colors, and details using right or top menus to enhance visual appeal. Draw inspiration from other Templates Community layouts and incorporate suitable images or features that complement your design.

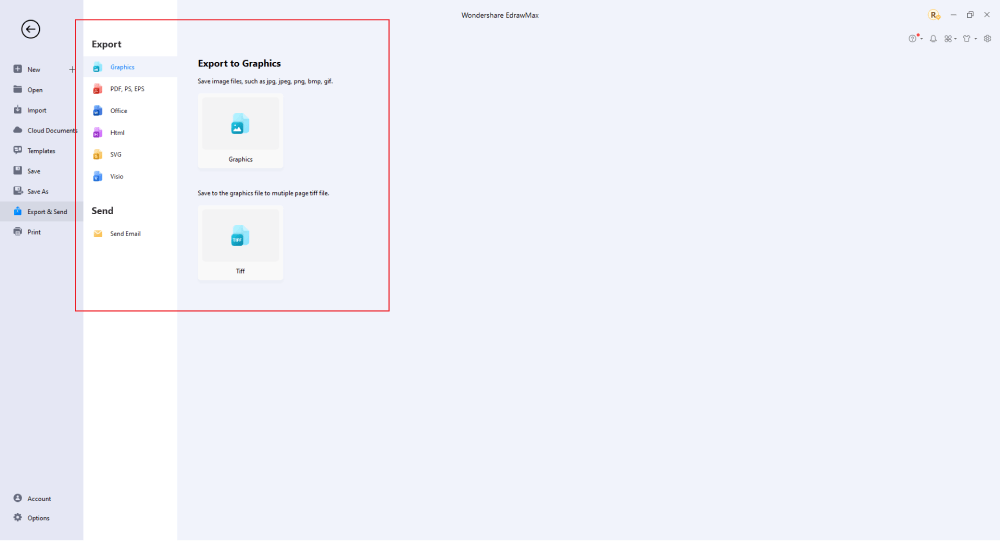

Step6 Finalize and Export

Once your Quality Control Flowchart is complete, collaborate with workgroups using Cloud-based files for feedback. EdrawMax supports export to multiple formats including Graphics, Microsoft Office, HTML, PDF, Visio, and others. Share via social networks or email, or present using "Presentation Mode."

Creating Quality Control Flowcharts in EdrawMax is straightforward: select templates, customize continuously, and utilize professional symbols to enhance your plans. For additional guidance, explore tutorial videos on our YouTube channel.

6. Quality Control Flowchart Examples & Templates

Various tools exist for process control and issue resolution, with quality control flowcharts being the most favored among seven prominent options. Quality Control Flowchart Examples provide simplified understanding of complex processes, clearly demonstrating connections between different steps.

For additional flowchart examples and templates, explore Flowchart Examples for comprehensive resources!

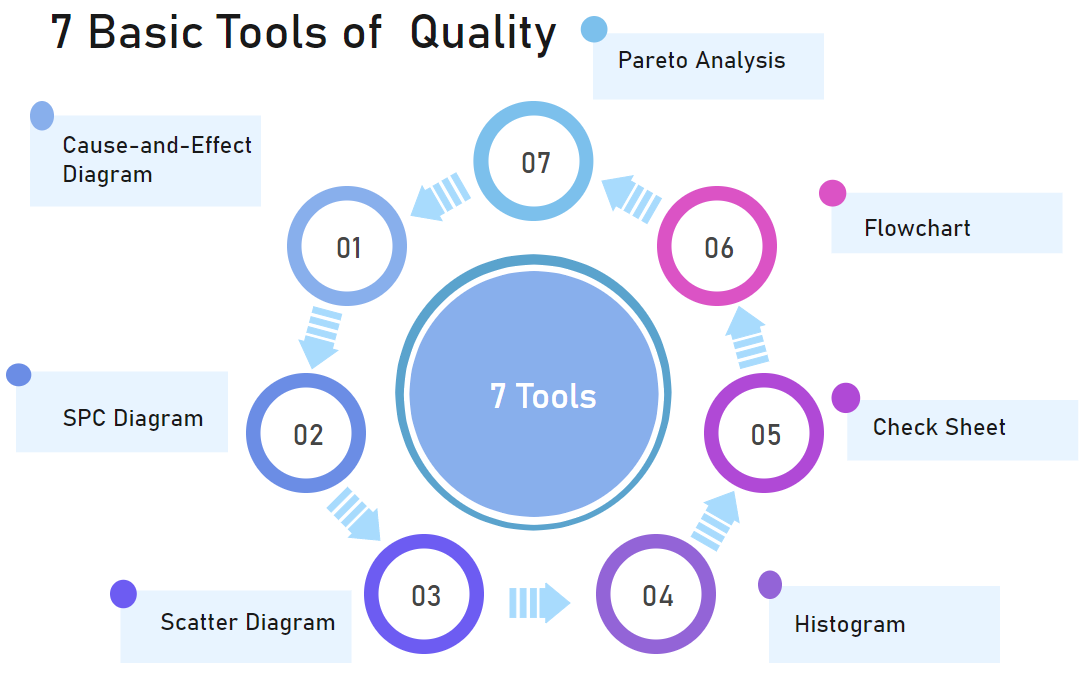

Example 1: 7 Basic Tools Of Quality

Quality control flowcharts benefit any business plan significantly. EdrawMax provides 10 varieties of different templates including workflow and data flow diagrams. Present your stories through charts, rack diagrams, and visual content using EdrawMax's comprehensive tools.

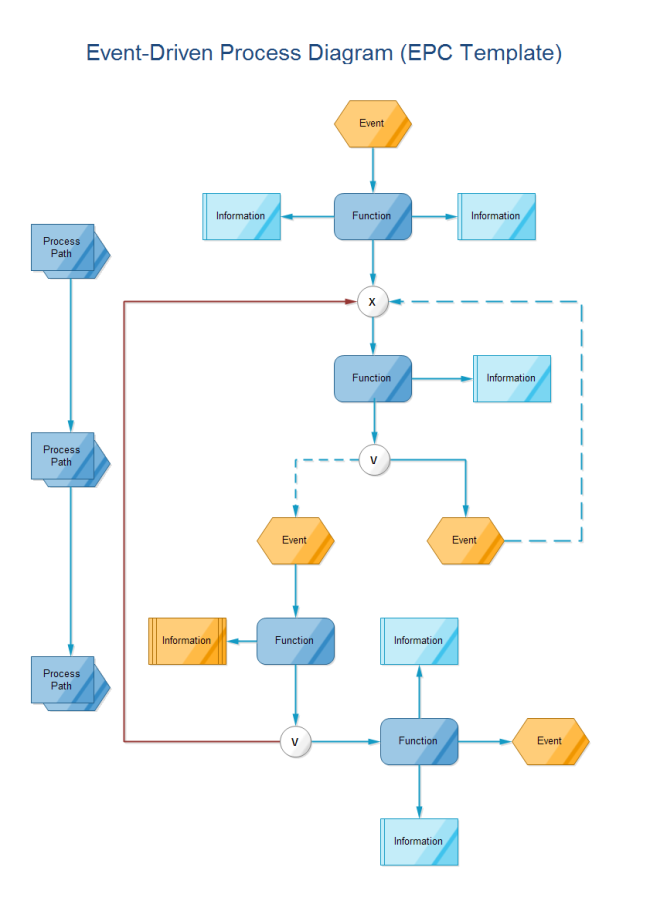

Example 2: Event-Driven Process Diagram Template

EdrawMax offers free downloadable and printable customizable event-driven process diagram templates that provide starting points for flowchart creation. The platform simplifies the process through intuitive steps and procedures.

Example 3: Production Planning and Control Process Template

The production planning and control process template represents one of EdrawMax's most useful templates, enabling flowchart creation for new products and equipment. Develop customized materials according to specific business plans using this versatile template.

Example 4: Quality Control Flowchart Template

Manufacturing flowchart examples help visualize product flows and identify process improvement opportunities. They facilitate collaboration with colleagues on addressing process inefficiencies effectively.

7. Free Quality Control Flowchart Software

EdrawMax represents free software for producing customized visual representations. Eliminate pencil and paper requirements for business plan flowcharts as EdrawMax delivers exceptional results. Its distinctive features make it the preferred choice for most users.

EdrawMax serves as a comprehensive diagramming tool for creating not only quality control flowcharts but various graphical illustrations. With well-equipped rack symbols, fonts, and extensive resources, server rack representations become exceptionally simple. Furthermore, EdrawMax enables diagram customization and multi-format saving capabilities.

Key EdrawMax features for Quality Control Flowchart creation:

- EdrawMax Quality Control Flowchart software maintains compatibility with Windows, Linux, and Mac systems, enabling online diagram access anywhere, anytime

- Over 280 diagram types including flowcharts, tree diagrams, mind maps, architectural diagrams, wiring plans, and more

- Download or export files in multiple formats including PDF, PNG, PPTX, MS DOCS, and JPEG

- Extensive library of customizable templates meeting all requirements, regularly updated by professionals with creative ideas completely free

- Advanced user-friendly interface ensures comfort even without design experience, featuring complete symbol sets and general art tools for customized drawings

- EdrawMax's user base exceeds 25 million people worldwide, presenting unique templates through creative approaches for maps, design models, organizational charts, and network diagrams

8. Final Thoughts

Quality management incorporates two essential components: processing methods and activities that maintain product quality. The quality control flowchart combines seven useful tools for quality control processes, providing understandable visual representations of product or service processing. It helps identify necessary apparatus and methods while impressing colleagues and companions. For creating attractive flowcharts, EdrawMax produces easily understandable diagrams that clearly illustrate every point.

Using EdrawMax reveals several amazing features that simplify Quality Control Flowchart creation and facilitate sharing through easy options. Export files into multiple formats and share works across social media platforms including Facebook, Twitter, LinkedIn, and Pinterest. Ultimately, EdrawMax serves as a comprehensive tool addressing all designing and drawing requirements effectively.

Flowchart Complete Guide

Explore this comprehensive guide covering flowchart types, symbols, and creation techniques for effective process visualization.